Looking for a reliable UK metal fabrication partner known for high quality and attention to detail?

Give us a call to discuss your next project

Drop us an email to discuss your next project

Metal Fabrication

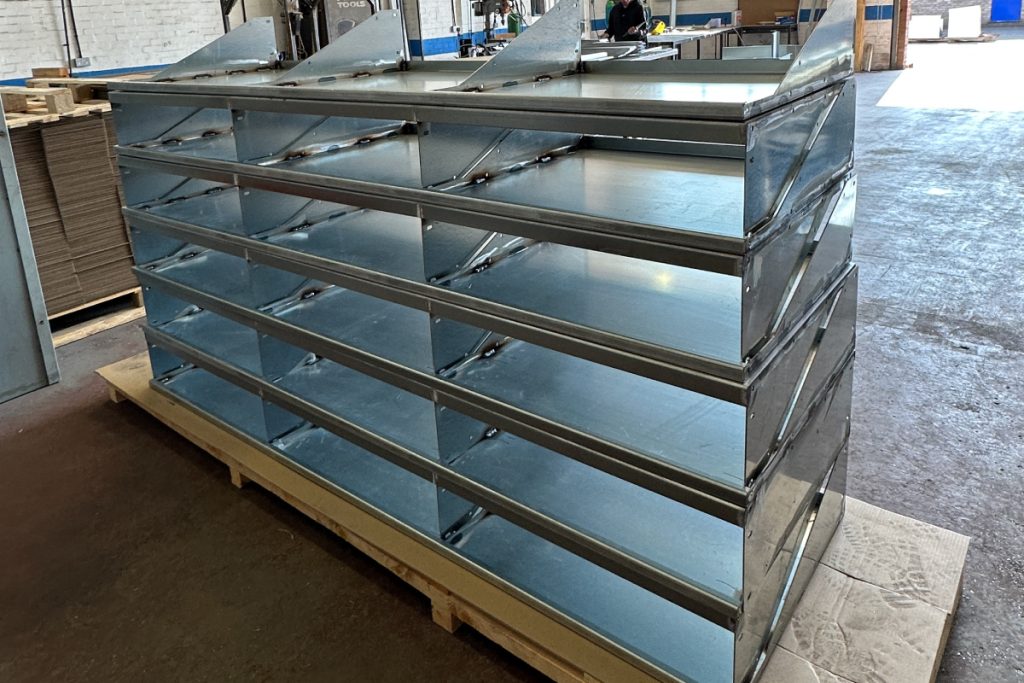

Metal Makers is your trusted partner in precision metal fabrication, offering expertise, innovation, and reliability. From bespoke architectural elements to agricultural and industrial solutions, we deliver enduring quality.

Our team specializes in fabricating custom solutions in Aluminium, Mild Steel, and Stainless Steel. With a variety of finishes available, including anodised aluminium and powder coating, Metal Makers provides the ideal material and finish for your project.

Our Products

Solutions driven manufacturing partner

We take pride in being a reliable metal fabrication and seeing ourselves as your manufacturing partner, offering an extensive range of versatile solutions that cater to diverse industrial and commercial needs. Our fabrication capabilities include:

Featured Projects

Why work

with us

Decades of Expertise

With decades of collective experience, Metal Makers brings a wealth of knowledge to every project. Our team ensures that your metalwork is crated with precision and expertise.

Transparent

Our pricing models is straightforward, with no hidden costs. You can trust that the quote you receive is comprehensive, ensuring clarity and confidence throughout the project.

On-Time

We understand the importance of staying on schedule. Metal Makers is committed to delivering projects on time and within budget, providing you with peace of mind and reliability.

Customer-Centric

We take a customer-centric approach, ensuring that your needs and visions are not just heard but integrated into the fabric of our work. We believe in building lasting partnerships.

Innovative

Our team constantly explores new techniques, materials, and design concepts to bring fresh perspectives to your projects.

Versatile

Our expertise spans a wide spectrum of industries, ensuring that your project benefits from a multidimensional approach to metal fabrication.

Transforming you vision into reality.

At Metal Makers, we believe in a seamless process that turns your ideas and drawings into tangible, precision-crafted metalwork. Our four-step journey ensures transparency, collaboration, and excellence from the initial inquiry to the final delivery.

/01

Initial Consultation and Vision Exploration

/02

Design and Concepts

/03

Precision Fabrication

/04

Timely Delivery and Quality Assurance

What our clients are saying

“Metal Makers consistently exceeds expectations with high quality and reliable service. Their attention to detail and commitment to excellence makes them stand out from others.”

“Metal Makers quality is very good and their response to enquiries for prices is impressive and we wouldn't use anybody else as we haven't found anyone that can better the Metal Makers service.

“With Metal Makers, you get high quality products delivered on time and within budget. Their dedication to excellence sets them apart in the industry.”

Frequently asked questions:

These sets of questions and answers by experts can help get a better understanding of our general service and processes.

Metal Makers are able to use a variety of different materials such as Mild Steel, Aluminium, Brass and Stainless Steel. We have a excellent understanding of the different types of materials, so are able to recommend different materials depending on the project’s requirements, considering factors such as application, environment and aesthetics.

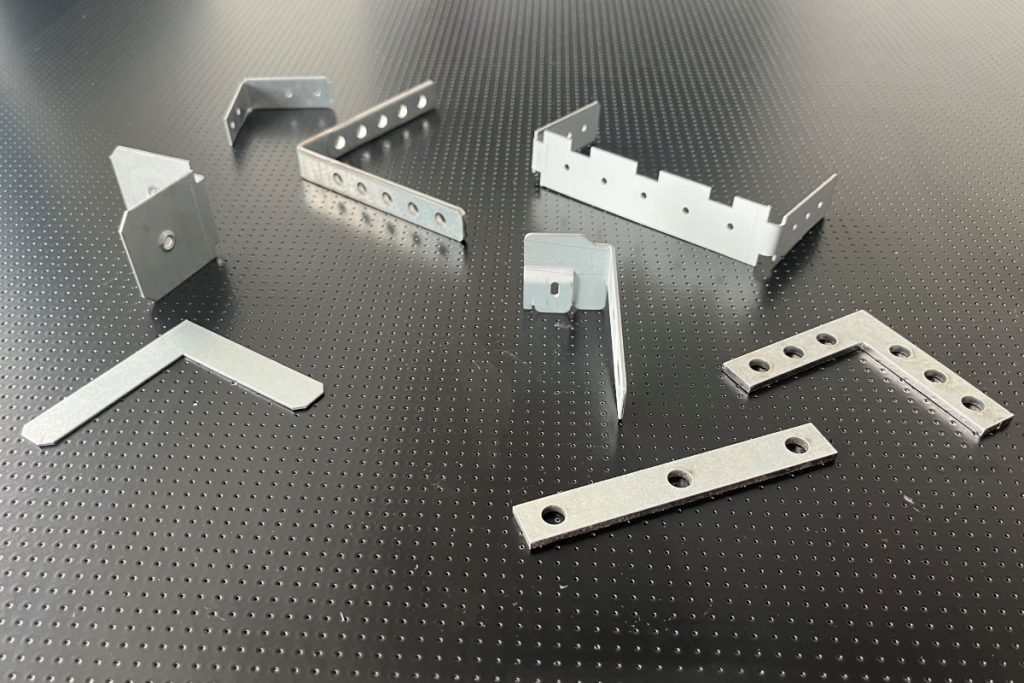

We are able to offer a fully encompassing range of metal fabrication services such as:

- Cutting: Shearing, laser cutting, water jet cutting and plasma cutting

- Forming: Bending, folding and rolling

- Joining: Welding (MIG and TIG), Riveting

- Machining: Drilling

- Assembly: Fitting and assembling components, Mechanical fastening (bolting, screwing)

- Finishing: Brushing, Linishing, Polishing, Coating (powder coating, anodising), Galvanising

Bespoke fabrication involves creating unique components or products based on specific design requirements. It caters to individual customer needs resulting in a bespoke solution made specifically for a certain situation, without the need for modification. In contrast, standard, off-the-shelf products are mass-produced and readily available for general use and may require modifying. Bespoke fabrication allows for greater flexibility, precision and the ability to meet unique project specifications.

The cost of a fabrication projects is influenced by several factors:

- Material Costs: The type and quantity of materials used.

- Labour Costs: The complexity of the fabrication process and the skilled labour required.

- Project Complexity: The intricacy of the design and the number of fabrication processes involved.

- Finishing Options: The chosen surface finish or coating for the final product.

- Project Size: The scale and volume of the fabrication project

- Customisation: Custom-designer components may incure additional costs compared to more standardised designs.

- Project Timeline: Urgent projects may incur expedited production costs.

Understanding these factors helps in estimating and managing the overall costs of a fabrication project effectively.